|

|

Information Box |

|

Trans-1,2-Dichloroethylene, Next generation solvent for

precision cleaning industry. To help the user

to escape from the continuous price increasing of n-Propyl

Bromide, Unistar is working on a new project to remove or

increase the flash point of 1,2-Trans. Candidates include

Methylene Chloride, HFC products. We have been successfully

increase the

flash point

to 50 degree C.

Our goal is to

create a affordable, steady supplying product to cleaning

industry.

|

|

|

|

|

Hot News |

|

n-PB price keep

jumping.

Because of the

shortage on bromine element, price of n-PB keep going up. It

breaks $2.00/lb recently. n-PB is losing its price

advantage.

Unistar will

expand its 1,2-trans production capacity to 5000MT/year. In

the new plant, a new production line of PERC will be setup

simultaneously. the expected production capacity of PERC

will be 10000MT/year

|

|

|

|

|

Article Regarding Vapor Degreasing Solvent

Organic Solvent Cleaning

By

Wayne L. Mouser, Group Vice President of

Forward Technology

www.forwardtech.com

|

Vapor phase

solvent cleaning has been a mainstay

in the metal processing industries

since the early 1940's. Its

popularity was driven by the ability

to quickly remove organics such as

oils, greases, lubricants, coolants,

and resins in a single step. The

part, at ambient temperature, is

lowered into a solvent vapor. The

vapor, hotter than the part,

condenses on the part and dissolves

the organics. The part then is

withdrawn to the freeboard area

where the solvent evaporates from

the part, leaving it clean, spot

free, and dry. A vapor degreaser as

shown in Fig 1 was inexpensive to

own and operate.

During the early

1970's, use of the most popular

chlorinated solvent,

trichloroethylene(TCE), dropped from

a high of 609 million pounds in 1970

to a low of 90 million pounds in

1992. TCE fell out of favor due to

environmental issues such as ground

water pollution and air pollution

since TCE is a volatile organic

compound (VOC). Use of TCE was

partially replaced by

1,1,1-trichloroethane in the early

1970's and then by CFC-113 in the

late 1970's and 80's. |

Fig. 1 |

|

Both CFC-113 and

1,1,1-tri were considered to be very

safe from a worker exposure point of

view. 1,1,1-tri was favored in the

metal working world while CFC-113

became the top choice in

electronics, aerospace, and many

other precision cleaning

applications. CFC-113 was effective,

low-cost, non-toxic, non-flammable,

and considered to be environmentally

preferable until the discovery of

the hole in the ozone.

In September

1987, the international community

signed an agreement to reduce the

usage of CFC-113 by 50%. At that

time, computer modeling suggested

that such a reduction would halt

theozone depletion. It was later

learned through more sophisticated

examination that a complete ban on

CFC-113 and 1,1,1-tri was needed to

protect the ozone layer. Worldwide

consumption of CFC-113 peaked at 279

million pounds in 1989 and was

banned in the U.S. in 1992.

1,1,1-triwas phased out at the end

of 1995.

The impending

loss of these two important solvents

started a frantic stampede by users

and suppliers to alternative

processes such as aqueous,

semi-aqueous, and alcohol based

processes. No clean fluxes and

soldering processes were developed

in the electronics industry. Metal

working primarily shifted to aqueous

cleaning and to no clean steps such

as vanishing oils. Precision

cleaning applications that could not

tolerate water switched to vapor

phase alcohol or engineered solvent

systems.

Today, a number

of new solvent choices have come on

the scene and recent advances in

equipment have allowed the safe use

of some of the older, more toxic,

solvents. The advantage to the user

is smaller foot print of the

equipment, faster throughput time,

and spot free finish produced by

vapor phase drying as opposed to

mechanical drying utilized in

aqueous processes.

The choice of the

right solvent to use is not an easy

one. Several factors must be

considered.

- Is the solvent compatible

with the substrate to be cleaned

and can it dissolve the

contaminant?

- Is the solvent and equipment

safe for the worker?

- Does the solvent and amount

used comply with local, state,

and federal regulations and

company policy?

- Does the solvent, process,

and equipment match the required

production rate and product

flow?

- Is the solvent and equipment

within budget?

In order to

choose a candidate solvent for a

specific process, it is helpful to

consider the physical properties.

Each of the solvents listed in Table

1 are commercially available and are

acceptable as vapor phase solvents.

This list is not inclusive by any

means. Several solvent suppliers

provide excellent solvents that are

an azeotrope or blend of the listed

solvents for specific purposes. As

an example, the HFC, HFE solvents

can be blended with trans-1,

2-dichloroethylene where additional

solvency is required. They are used

in a wide range of applications and

a review of the properties will

assist in choosing the right solvent

for a specific application. |

Table 1

|

Kauri-Butano

Value |

Boiling

Point °C |

Vapor

Density |

Surface

Tension Dynes/cm |

Vapor

Pressure Mm Hg 25 C |

Heat of

Vaporization cal/g |

|

Trichloroethylene |

129 |

87° |

4.53 |

28.7 |

70 |

56.4 |

|

Perchloroethylene |

90 |

121° |

5.76 |

32.3 |

20 |

50.1 |

| Methylene

Chloride |

136 |

39.8° |

2.93 |

27.2 |

350 |

78.7 |

| n-Propyl

Bromide |

125 |

71° |

4.25 |

25.3 |

111 |

58.8 |

| HCFC

(AK-225 AES) |

41 |

52° |

7 |

16.8 |

291 |

40.6 |

| HFC (Vertrel

XP) |

9.4 |

52° |

7.86 |

15.1 |

253 |

Tbd |

| HFE-71IPA |

10 |

54.8° |

7.51 |

14.5 |

207 |

39.5 |

| Acetone |

NA |

56° |

2 |

22.7 |

229 |

134.7 |

|

Cyclohexane |

58 |

80.7° |

2.9 |

24.9 |

95 |

85 |

| Isopropyl

Alcohol |

NA |

82° |

2.1 |

21.7 |

40 |

166.1 |

| N-Methyl

Pyrrolidone (NMP) |

350 |

204.3° |

3.4 |

40.7 |

0.24 |

127.3 |

| D-Limonene |

67 |

154° |

4.73 |

25 |

2 |

NA |

| Trans-1,

2-Dichoroethylene |

117 |

47.8° |

3.34 |

27.5 |

330 |

72 |

|

|

The Kauri-Butanol

Value is a measure of solvency

power. It is important to choose a

KB value that matches the

contaminant to be removed and at the

same time does not affect the

substrate. An extreme example would

be removal of epoxy.About the only

solvent strong enough to attack

epoxy is N-Methyl Pyrrolidone (NMP).If

the substrate were steel, NMP would

be acceptable but if the substrate

were aprinted wiring assembly, NMP

would be too aggressive. Generally

the higher KB value solvents are

used for heavy organics such as oils

and greases. A good example

iscyclohexane that excels in removal

of rosin flux, oils, and heavy

greases. Lower KBvalue solvents are

used in critical cleaning where

particle removal and light organics

are found.

KB values are not

available for acetone and IPA.

Practical experience indicates that

acetone is a mild selective solvent

best used for adhesive or mild

organic removal. Cyclohexane excels

in removal of rosin flux, oils, and

heavy greases. IPA is the mildestof

the three and is used extensively in

critical cleaning for electronics,

medical implants, aerospace, disk

drive, or where a spot free

hydrophilic surface is required.

The Boiling

Point is important when the

contaminant is temperature sensitive

such as wax or when the substrate is

sensitive to temperature. An example

would be removal of wax with

Perchloroethylene with a boiling

point of 121 degrees C. Most waxes

will melt and degrease nicely at

that temperature but some substrates

could not tolerate that

temperature.It is also important to

consider the purity of the vapor

blanket in the machine. The higher

the boiling point, the more

likelihood of organic concentration

in the vapor. This could lead to

organic contamination of the

substrate during the drying phase.

Vapor Density

is a measure of the weight of the

vapor blanket where air = 1. Allof

the selected solvents are heavier

than air. That is good. It helps

keep the solvent in the machine.

Emissive solvent loss is a function

of the boiling point and the vapor

density. Also proper equipment

design can minimize emissive loss.

Surface

Tension is the storage of energy

at the surface of liquids. Surface

tension tries to minimize surface.

Imagine a droplet of water on a flat

surface. The high surface tension of

water (78) causes the water to form

a bead. This force makes it

difficult for water to penetrate

tight crevices. The surface tension

of the selected solvents is

muchlower. A similar sized droplet

of any of the solvents would spread

over the surface rather than bead

up. The solvent is able to creep

into tight spaces, dissolve

contaminate, and then be flushed out

with fresh solvent. The lower the

surface tension, the better.

Vapor Pressure

measures the pressure the vapor

exerts over the liquid at

equilibrium. This physical

characteristic determines what

solvents can be used as the sole

solvent in vapor phase cleaners.

Note that NMP and D-limonene have

low vapor pressures. They also have

high boiling points and cannot be

easily converted from liquid to

vapor. Both are excellent solvents,

but should only be considered in

co-solvent systems where a second

solvent such as isopropyl alcohol

can be used as the rinsing and vapor

phase portion of the cleaning cycle.

Heat of

Vaporization is the measure of

energy necessary to convert liquid

to vapor at the boiling point. Note

that most of the chosen solvents

have a much lower heat of

vaporization than the energy

required for water (539 cal/gm).

These solvents are much easier to

dry from the part as compared to

water. That means quicker drying

times and lower energy costs.

Once candidate

solvents have been chosen for

solvency and compatibility, the next

step is to evaluate the solvent and

equipment for worker safety and

regulatory compliance. There are

many methods of evaluation and each

user must determine the degree of

importance of various safety issues

and also must comply with local

requirements as well as company

dictated requirements. Some

important safety concerns are listed

in Table 2. |

Table 2

|

HAPs |

TLV |

Flash

Point Closed Cup °C |

Total

Hazard Value |

|

Trichloroethylene |

Yes |

50 |

None |

41.3 |

|

Perchloroethylene |

Yes |

25 |

None |

37.5 |

| Methylene

Chloride |

Yes |

25 |

None |

30.1 |

| n-Propyl

Bromide |

No |

100* |

None |

9.2 |

| HCFC

(AK-225 AES) |

No |

50 |

None |

5.2 |

| HFC (Vertrel

XP) |

No |

213** |

None |

12.7 |

| HFE-71IPA |

No |

750/400 |

None |

7.3 |

| Acetone |

No |

750 |

-17 |

15.9 |

|

Cyclohexane |

No |

300 |

-20 |

23.5 |

| Isopropyl

Alcohol |

No |

400 |

0.6 |

14.2 |

| N-Methyl

Pyrrolidone (NMP) |

No |

100 |

93 |

7.1 |

| D-Limonene |

No |

NE |

49 |

7.8 |

| Trans-1,

2-Dichoroethylene |

No |

200 |

2.2 |

28.6 |

|

|

|

* Supplier recommendation |

|

** Supplier calculated AEL |

|

|

HAPs Title

III of the 1990 Clean Air Act

Amendments lists 189 compounds that

are classified as hazardous air

pollutants (HAPs). At the very

least, the HAPs solvents must be

used in a NESHAP compliant machine

and their emission to the atmosphere

must be tightly controlled. Due to

their known toxicity and potential

damage to the environment, it is the

opinion of this writer that HAPs

solvents should only be used in

airtight machines.Many companies

have made the decision to move to

alternate solvents to avoid the

complications of dealing with HAPs

solvents.

TLV.

Threshold Limit Values are

guidelines established by the

American Conference of Governmental

Industrial Hygienists (ACGIH) to

assist industrial hygienists in

making decisions regarding safe

levels of exposure to various

hazards found in the workplace. TLV

reflects the level of exposure that

the worker can experience without an

unreasonable risk of disease or

injury. A low TLV number should

suggest the solvent be used in an

airtight machine or that the

workplace and worker be carefully

monitored so that the exposure level

does not exceed the TLV.

Flash Point.

Any solvent listed with a flash

point should only be used in

equipment properly designed for low

flashpoint or combustible solvents.

There are many advantages to taking

this route. Solvents such as IPA,

cyclohexane, and acetone are

excellent solvents relative to their

physical properties and low

toxicity. They clean well and

produce a spot free finish. They are

easy to dispose of and are

inexpensive, actually cheap when

compared with other alternatives.

The disadvantage is since they are

flammable; they require more

expensive equipment to safely

operate.

Total Hazard

Value. There are many methods of

evaluating the safety of solvents.

TLV, VOC, HAPs, PEL, AEL, ODP to

name a few. The list goes on and on.

If you have an environmental, health

and safety staff, they are no doubt

experts in this field. If you need

help, you might want to consider a

rating system called the Indiana

Relative Chemical Hazard Score (IIRCHS)developed

by the

Clean Manufacturing Technology and

Safe Materials Institute (CMTI)

located at Purdue University. If you

don't find the chemistry you are

interested in, give Shayla Barrett,

Process Engineer, a call. Shayla was

very helpful in the preparation of

this paper.

The formula for

the assignment of the total hazard

value covers many health and

environmental concerns. An excellent

reference is an article entitled

"Solvent by the Numbers" by Charlie

Simpson published in the January

2002 CleanTech magazine. |

|

Now that solvent

compatibility and safety have been

addressed, the next step is to

consider process flow and production

capacity. This will determine the

type of equipment you will need.

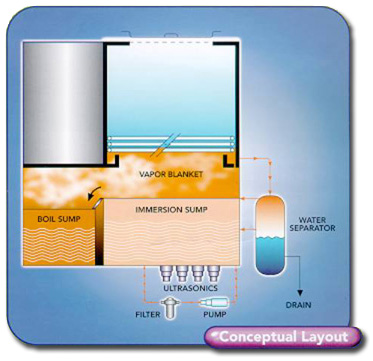

Product offerings start with manual

open top designs (Fig 2).

|

Fig. 2 |

|

To fully

automated machines capable of

cleaning a basket of parts every

couple minutes (Fig.3). |

Fig. 3 |

|

The solvent of

choice will also impact the

equipment decision. Some of the

solvents are acceptable to use in

open top manual machines, while

other solvents, because of their

environmental and worker safety

concerns, are best used in air tight

or vacuum machines (Fig. 4). |

Fig. 4 |

|

Low flash point

solvents require equipment (Fig. 5)

built specifically to address

flammability issues. They are

compatible with acetone, cyclohexane,

IPA, NMP, D-Limonene, as well as the

other listed solvents that do not

exhibit a flash point. |

Fig. 5 |

| The final step is

the all-important budget for the

project. A solvent cost comparison

appears in Fig.6. |

Fig. 6 |

|

Equipment cost

varies with the size, materials of

construction, cleaning cycle, and

degree of automation. Prices can

range from less than $10,000 to over

$1,000,000.

Vapor phase

solvent cleaning is an important and

valuable tool. This cleaning process

offers complete washing, rinsing,

and drying in a small footprint

while minimizing energy, floor

space, and process time. With

today's efficient equipment and safe

solvents, the process is expected to

flourish. |

|

| |

| |

|

|